Carbon Capture: Integrated Polymer Facades

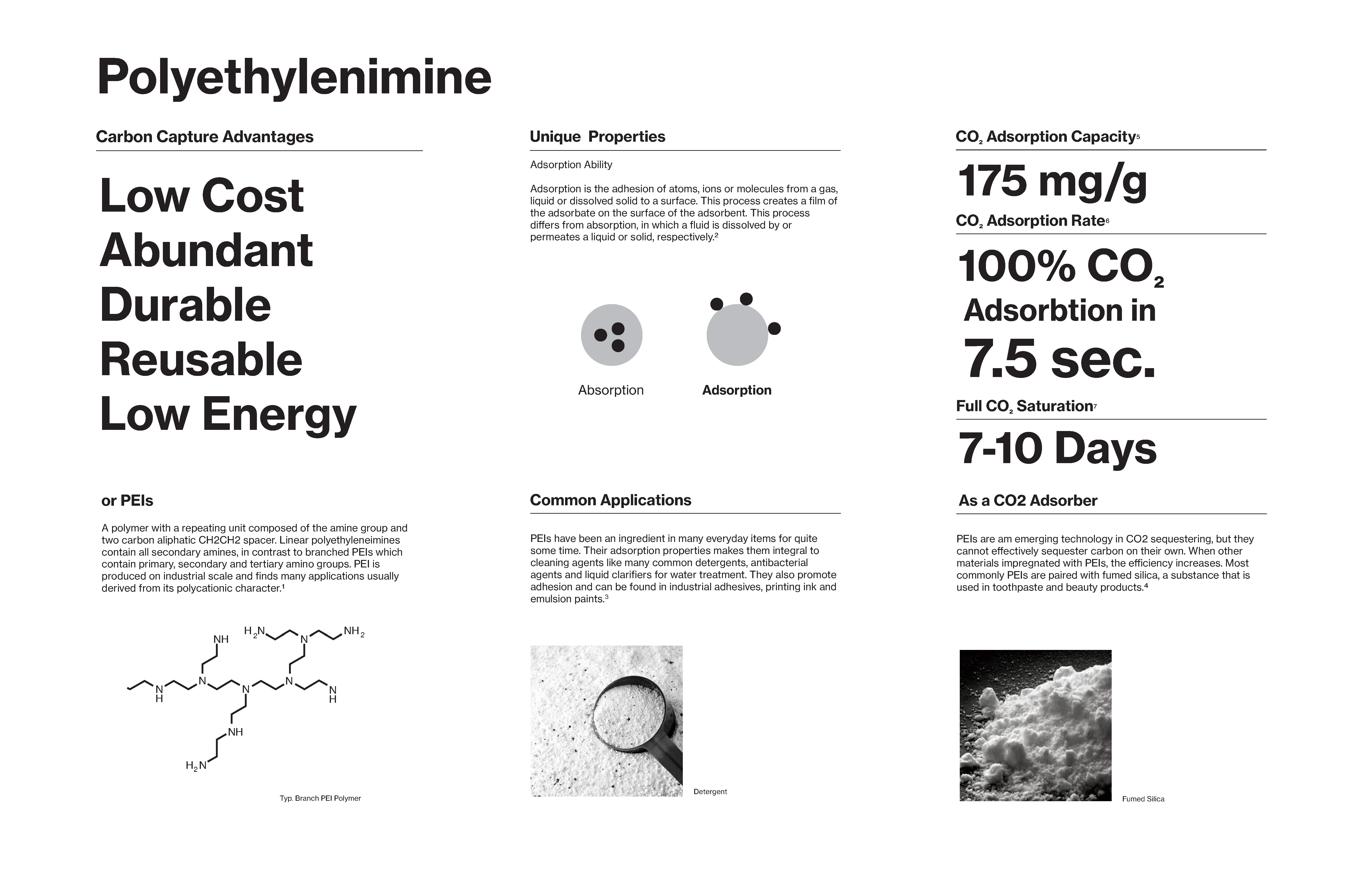

This is the culmination of a semester long research project focused on carbon sequestering materials. These materials are part of a larger CO2 system known as carbon capture and storage, specifically post carbon capture. Although there are many low-tech organic materials that sequester carbon, the project focused on a breakthrough in polymer research; chains of polymers known as Polyethyleneimines or PEIs for short. These polymers have unique adsorption qualities that allow the CO2 molecules in ambient air stick to the surface of the polymer, and their potential for architectural carbon sequestering systems has largely been untapped. They are low cost, plentiful, require low energy to manufacture and require a much lower energy input than any other material to release the trapped CO2 on their surface. Like most carbon sequestering materials, they do reach a saturation point, where they can’t adsorb any more CO2 from the ambient air. Researchers have successfully used pure steam in the de-adsorption process to release all the carbon.

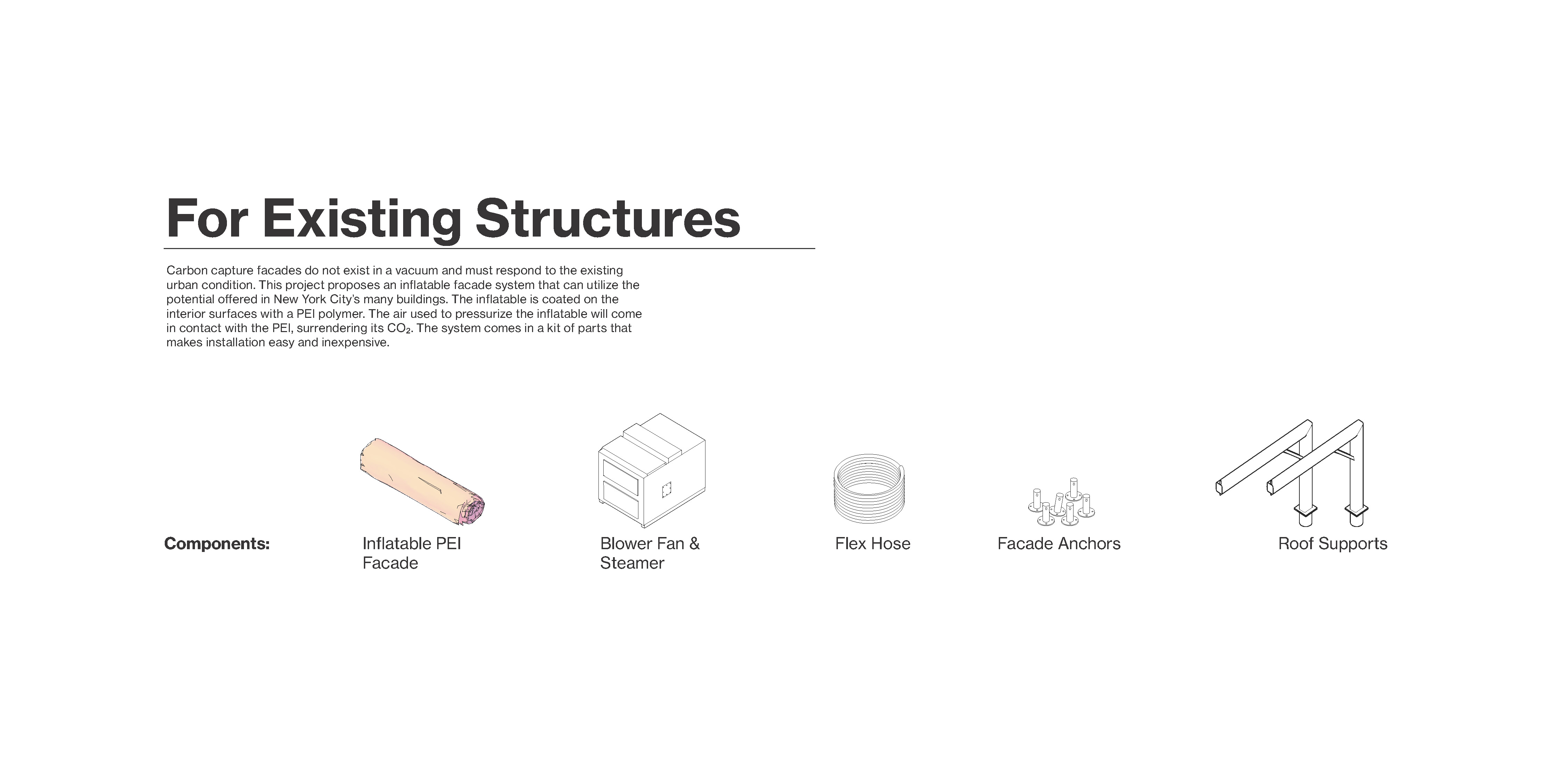

The project proposes using these PEIs to create a dynamic façade system that sequesters carbon on the urban scale, while borrowing language of past experimental architecture. Because of the nature of the material, its need for constant air flow to maintain maximum efficiency and need to be cleaned in order to release the carbon, the new façade typology will be a series of inflatable membranes. The interior surface will be coated with PEIs that clean the air that is fed through the fan system. Every façade will be covered with one of these systems in the future to tap into the plentiful surface area available in New York City. The proposal is in two parts; one for adapting existing facades and the other is a possible solution for new construction.

This is the culmination of a semester long research project focused on carbon sequestering materials. These materials are part of a larger CO2 system known as carbon capture and storage, specifically post carbon capture. Although there are many low-tech organic materials that sequester carbon, the project focused on a breakthrough in polymer research; chains of polymers known as Polyethyleneimines or PEIs for short. These polymers have unique adsorption qualities that allow the CO2 molecules in ambient air stick to the surface of the polymer, and their potential for architectural carbon sequestering systems has largely been untapped. They are low cost, plentiful, require low energy to manufacture and require a much lower energy input than any other material to release the trapped CO2 on their surface. Like most carbon sequestering materials, they do reach a saturation point, where they can’t adsorb any more CO2 from the ambient air. Researchers have successfully used pure steam in the de-adsorption process to release all the carbon.

The project proposes using these PEIs to create a dynamic façade system that sequesters carbon on the urban scale, while borrowing language of past experimental architecture. Because of the nature of the material, its need for constant air flow to maintain maximum efficiency and need to be cleaned in order to release the carbon, the new façade typology will be a series of inflatable membranes. The interior surface will be coated with PEIs that clean the air that is fed through the fan system. Every façade will be covered with one of these systems in the future to tap into the plentiful surface area available in New York City. The proposal is in two parts; one for adapting existing facades and the other is a possible solution for new construction.

The future city will not materialize in an instant and must deal with the existing urban condition. Part One proposes inexpensive components that will allow any building to purchase and install their own inflatable PEI façade. The semi-permanent façade is hung from the roof, inflated with a blower fan, and tied down with anchor components. As you can see from the case study, one building could potentially remove 24.6 kg of CO2 per week. The nature of this design makes it easily deployable for any building owner.

In the second phase, new construction will be designed to maximize contact with the interior coated membranes of the PEI Polymer. Based off similar inflatable polymer facades construction, new buildings will be comprised of a double skin to increase carbon capture via air to solid contact with the PEI membranes while also combating some of the negative aspects of traditional polymer facades. Just like the first example, the blower fan introduces CO2 at the top of the system and the air is cleaned as it reaches the bottom of the façade.

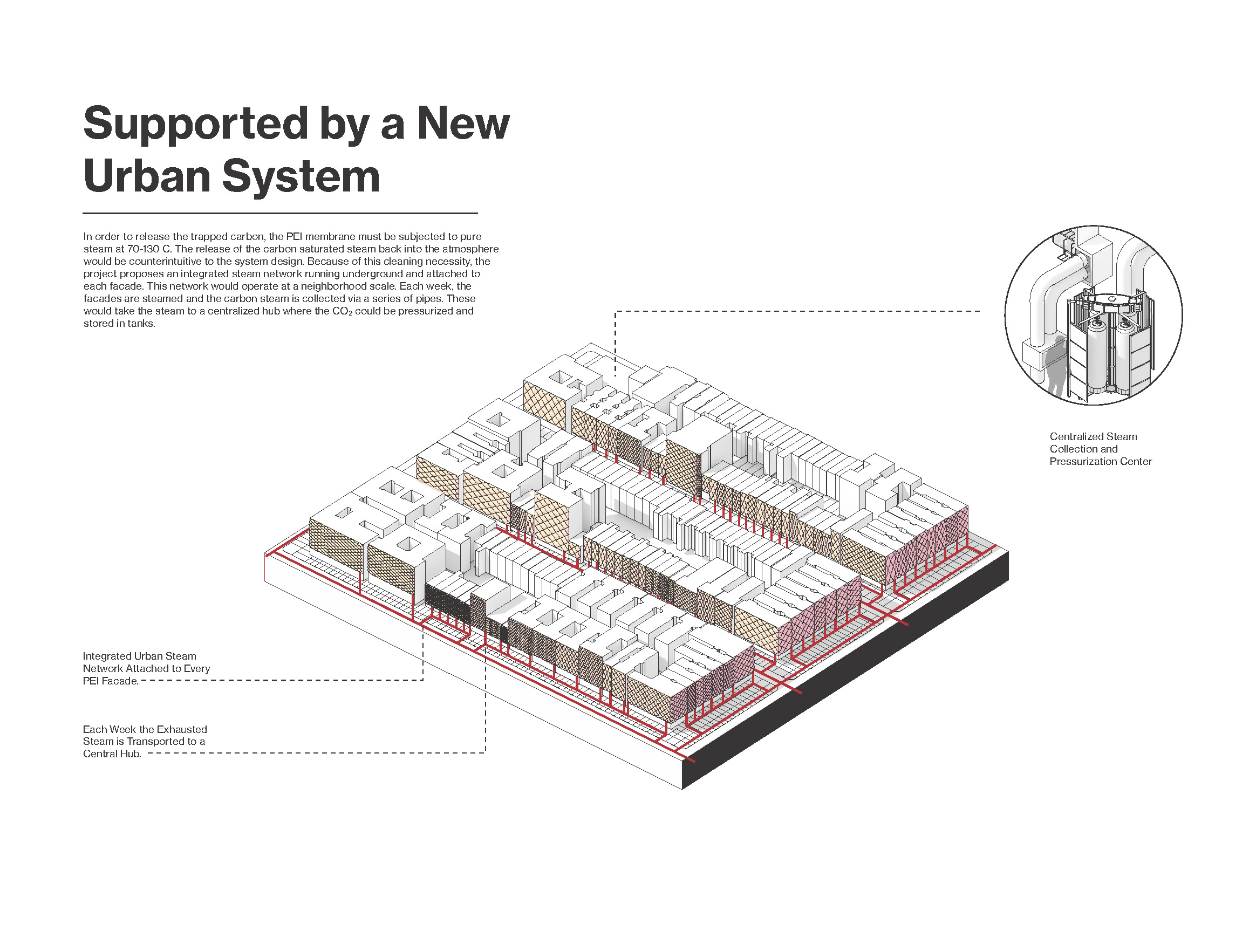

Third, because the carbon needs to be released, compressed and stored, there needs to be a system for collecting the CO2 steam mixture. The system depends on an integrated neighborhood network of steam channels to achieve that goal. Every week the neighborhood would clean the facades and send the steam to a centralized station that would consolidate the CO2 in pressurized tanks. The captured Co2 could be used to make a variety of products that already exist.

In this new system, the façade becomes a dynamic part of the building, both technically and symbolically.